Now, by leveraging the BUNDLAR Platform, anybody, anywhere can create, edit, and deploy augmented reality experiences instantly and on a global scale. BUNDLAR is an 1871 Chicago based tech company, that allows users to create “bundles” of multimedia content like videos, interactive 3D graphics, and other enhancements over physical objects or space.

Historically, the convention in manufacturing has been to train workers using a combination of paper guides and computer tutorials. A clear downside to these methods is time. Generally, this style of training has to be implemented months before a new task is to be completed and administered in an office. AR solves this drawback by allowing for just-in-time training that takes place on site, mere minutes before workers have to complete a task.

Providing on site, as needed training allows workers to pivot to a company’s needs quickly and efficiently, as shown by a study conducted by EPRI and Ameren Illinois. The study, which tasked workers with completing maintenance and router installation, showed that the group provided with in-field training through an AR app completed their assigned tasks nearly twice as fast as the group of workers given their instructions on paper cards.

What makes digital “bundles” useful is that the subject matter experts are developing these AR digital materials with a simple drag-and-drop platform, making AR affordable and scalable. In a manufacturing context, those needs can be training, or providing clear instructions to solve a specific on-floor problem. The possibilities for application are limited only by the imagination and needs of the client.

To sustain growth and close the workforce gap, modern manufacturers need to embrace new technology. Collaboration between human workers and technology benefits both the workers and the company by decreasing inefficiencies and increasing productivity. AR can provide workers with just-in-time training and the on-site support they need to improve their performance. When it comes to innovation in manufacturing, the future is augmented.

Request a live demo to learn more about the BUNDLAR Platform and how AR drives growth!

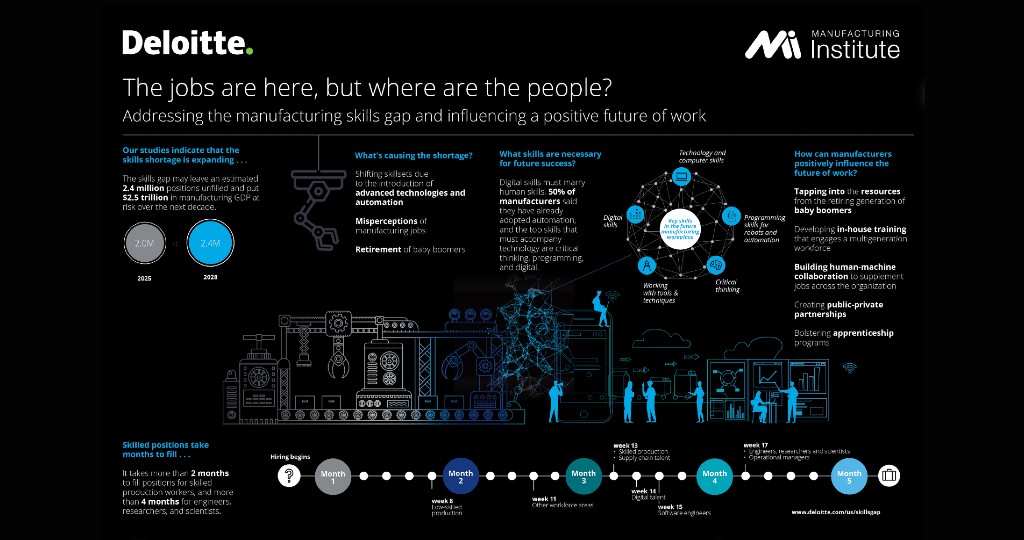

As we move into the new decade it’s clear that rapid innovation is needed to push the manufacturing industry forward. Studies conducted over the last few years have shown that the U.S is in the midst of a growing industrial workforce gap. In other words, openings for U.S manufacturing jobs are continuing to increase, while the pool of qualified candidates is decreasing.

According to a study conducted by Deloitte and The Manufacturing Institute, the growing industrial workforce gap may “leave an estimated 2.4 million positions unfilled between 2018 and 2028”. Manufacturing work is changing and nowadays it requires a highly skilled labor force with college education or certification. That means more intricate training that is taking longer to complete.

Experts are exploring the use of augmented reality (AR) to fill the education gap needed to fill the vacant manufacturing jobs. AR is a technology that places digital content in physical space. This can be done using a mobile device or tablet to effect sensory inputs using sound, video, interactive 3D graphics and more. It isn’t a new technology, but it is only in the last decade that significant strides have been made to make AR into a mainstream tool, one that household names like Google and Microsoft have invested in by making their hardware AR capable.

Two large hurdles to mass adoption of AR have been:

- The need for a designated developer who can create applications that can display AR experiences

- The inability to update and edit them when the user chooses — to make it a repeatable process.

Now, by leveraging the BUNDLAR Platform, anybody, anywhere can create, edit, and deploy augmented reality experiences instantly and on a global scale. BUNDLAR is an 1871 Chicago based tech company, that allows users to create “bundles” of multimedia content like videos, interactive 3D graphics, and other enhancements over physical objects or space.

Historically, the convention in manufacturing has been to train workers using a combination of paper guides and computer tutorials. A clear downside to these methods is time. Generally, this style of training has to be implemented months before a new task is to be completed and administered in an office. AR solves this drawback by allowing for just-in-time training that takes place on site, mere minutes before workers have to complete a task.

Providing on site, as needed training allows workers to pivot to a company’s needs quickly and efficiently, as shown by a study conducted by EPRI and Ameren Illinois. The study, which tasked workers with completing maintenance and router installation, showed that the group provided with in-field training through an AR app completed their assigned tasks nearly twice as fast as the group of workers given their instructions on paper cards.

What makes digital “bundles” useful is that the subject matter experts are developing these AR digital materials with a simple drag-and-drop platform, making AR affordable and scalable. In a manufacturing context, those needs can be training, or providing clear instructions to solve a specific on-floor problem. The possibilities for application are limited only by the imagination and needs of the client.

To sustain growth and close the workforce gap, modern manufacturers need to embrace new technology. Collaboration between human workers and technology benefits both the workers and the company by decreasing inefficiencies and increasing productivity. AR can provide workers with just-in-time training and the on-site support they need to improve their performance. When it comes to innovation in manufacturing, the future is augmented.